Discover the Various Usages and Benefits of Epoxy Injection Molding in Modern Production

Epoxy shot molding is transforming the way you consider production. By taking advantage of the one-of-a-kind buildings of epoxy materials, this procedure supplies durable and accurate elements with remarkable effectiveness. You could be surprised to find out exactly how it's being used in industries such as auto and aerospace. As we discover its applications and advantages, you'll find why this technique is becoming vital in contemporary manufacturing techniques. What makes it so advanced?

Comprehending Epoxy Injection Molding

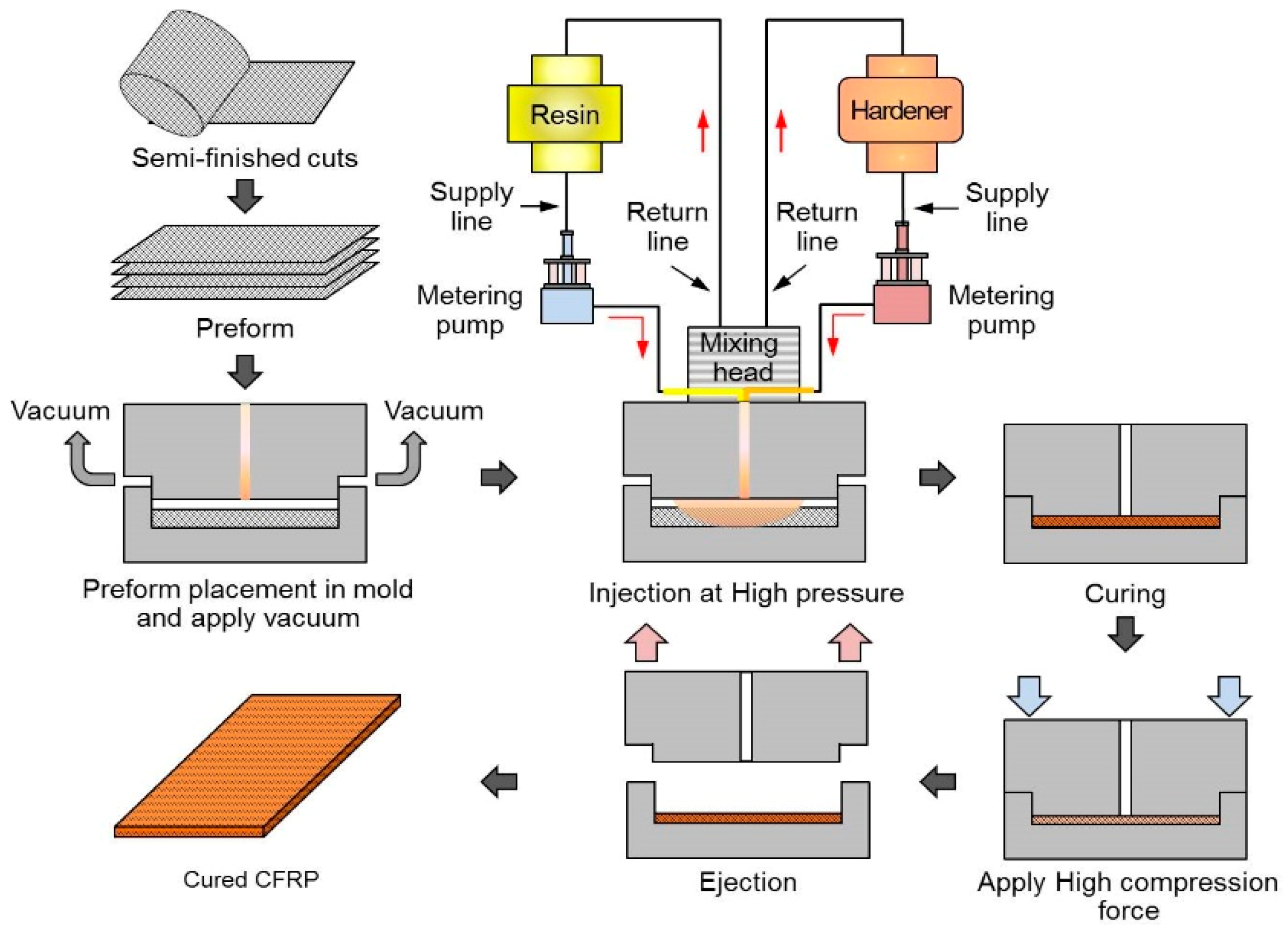

When you check out epoxy shot molding, you'll find it's an extremely effective process for producing durable and exact components. This method makes use of warmed epoxy material, which you inject into a mold and mildew under stress, enabling it to fill up every detail. The outcome? Top quality elements that meet precise specifications.You'll notice that the procedure is suitable for creating complicated geometries, making it a preferred choice in different sectors, consisting of automobile, aerospace, and electronics. Epoxy injection molding likewise supplies excellent surface coatings, which can decrease the need for added ending up processes.Moreover, it allows for quick manufacturing, aiding you fulfill limited deadlines without giving up quality. Recognizing this process equips you to harness its abilities efficiently, making your manufacturing procedures more affordable. By choosing for epoxy shot molding, you can attain the precision and toughness your projects demand, guaranteeing your items stand the test of time.

Secret Advantages of Epoxy Resins

Epoxy resins come with an array of advantages, their exceptional stamina and resilience stand out the most. You'll locate that these resins can withstand severe conditions, making them perfect for requiring applications. Their chemical resistance is another vital benefit; they withstand solvents, acids, and wetness, guaranteeing long life in different environments.When you use epoxy, you're likewise getting excellent attachment properties, enabling them to bond effectively with different products. This flexibility indicates you can create strong, trusted items utilizing less product, which can save you money in the long run.Additionally, epoxy materials heal quickly, which speeds up production times. You won't need to wait lengthy to see results, aiding you meet limited target dates. Their aesthetic finish can boost the look of your items, giving them a sleek appearance that appeals to consumers. Generally, epoxy materials supply an effective mix of performance and worth.

Applications in the Automotive Market

As the automotive sector remains to progress, epoxy injection molding plays an essential role in improving vehicle efficiency and toughness. You'll locate that epoxy resins are used in various auto parts, from structural parts to aesthetic finishes. Their outstanding bond residential properties assure that different materials bond properly, which is essential for producing lightweight yet strong components.Additionally, epoxy shot molding enables complicated geometries, enabling suppliers to make detailed parts that boost aerodynamics and decrease weight. This not only enhances fuel effectiveness yet likewise adds to general vehicle safety.Moreover, the chemical resistance of epoxy makes it ideal for parts subjected to extreme environments, such as engine parts and fuel systems. By integrating epoxy injection molding right into production, you're ensuring that lorries are not only dependable yet additionally geared up for the demands of modern driving. This technology genuinely stands for a considerable innovation in automobile production.

Aerospace Innovations With Epoxy Shot Molding

Epoxy shot molding is revolutionizing the aerospace market by providing light-weight, sturdy components that improve airplane efficiency. You'll locate that this modern technology allows makers to develop elaborate styles and intricate shapes, which are vital in enhancing the rules of aerodynamics. By utilizing epoxy, you're taking advantage of its outstanding thermal and chemical resistance, making it optimal for various aerospace applications.Imagine the capacity of using epoxy in parts like wing frameworks or body components. Not just does it reduce weight, but it additionally adds to improved fuel efficiency. You'll appreciate exactly how this technology leads to longer trip varieties and lower operational expenses for airlines.Additionally, the accuracy used by epoxy shot molding guarantees that each part meets rigorous aerospace standards, improving safety and security and dependability. As the industry continues to introduce, you'll see epoxy shot molding play a crucial function in the future of aerospace technology, driving improvements that make flight much safer and more efficient.

Enhancing Item Longevity and Stamina

When you select epoxy injection molding, you're boosting your items' longevity and toughness significantly. With enhanced influence resistance and boosted bond buildings, your things can stand up to even more damage. Plus, the temperature and chemical stability of epoxy guarantees that they keep integrity also in severe problems.

Improved Effect Resistance

Improved effect resistance is among the standout benefits of epoxy injection molding, making your products not just more long lasting yet likewise considerably more powerful. You're spending in parts that can endure hefty loads and stand up to damages from exterior forces when you pick epoxy injection molding. This improved stamina indicates less item failings and longer life-spans, inevitably conserving you cash on replacements and repair services. Whether you're creating automotive parts or customer goods, the capacity to soak up shocks without damaging or fracturing is necessary. Your items will certainly perform better popular settings, giving you a competitive side. By focusing on impact resistance in your designs, you'll guarantee your products can handle whatever challenges come their way, enhancing your overall credibility out there.

Boosted Adhesion Qualities

Solid adhesion residential or commercial properties considerably boost the longevity and toughness of your products. When you make use of epoxy injection molding, you're guaranteeing that the materials bond properly, which lowers the danger of delamination or separation gradually. This means your end products can endure greater stresses and strains, making them ideal for requiring applications.Moreover, improved bond lessens the chance of flaws or failures, bring about higher consumer complete satisfaction. With more powerful bonds, your products keep their stability even under extreme problems, causing longer life expectancies and decreased requirement for replacements. Eventually, buying epoxy shot molding not just increases the efficiency of your items yet likewise strengthens your brand name reputation for quality and dependability. You'll observe the distinction in resilience and stamina.

Temperature and Chemical Stability

Temperature and chemical security are vital variables that considerably boost the longevity and stamina of your items. By utilizing epoxy injection molding, you produce parts that endure severe temperature levels and stand up to chemical deterioration. This implies your items maintain their stability in harsh settings, whether they're subjected to high warm or corrosive materials. The durable nature of epoxy warranties that your products don't warp or damage down, expanding their life expectancy considerably. Additionally, this stability converts into lower maintenance prices and fewer substitutes, which is a win for your profits. With epoxy, you're not just producing items; you're spending in durable remedies that satisfy the demands of modern-day production. Welcome these advantages, and see your products grow in open markets.

Reducing Waste and Improving Performance

As you check out the advantages of epoxy injection molding, you'll find that decreasing waste and boosting effectiveness go together. This procedure reduces product waste by utilizing specific quantities of epoxy, guaranteeing you obtain one of the most from your resources. With mindful control, you can prevent excess product, bring about cost financial savings and less ecological impact.Moreover, epoxy injection molding enhances efficiency by click over here simplifying manufacturing cycles. The fast curing times of epoxy enable for faster turn-around, suggesting you can generate even more parts in much less time. This not just enhances your result however likewise reduces lead times for your customers.Additionally, the toughness and strength of epoxy parts decrease the demand for constant replacements, additionally reducing waste. By selecting epoxy injection molding, you're not simply improving your processes, but you're likewise contributing to an extra lasting manufacturing setting.

Future Trends in Epoxy Shot Molding

As you look in advance on the planet of epoxy injection molding, you'll see amazing advancements on the perspective. Advancements in products, boosted automation, and a stronger concentrate on sustainability are set to improve the market. These patterns guarantee not just to enhance efficiency but likewise to decrease environmental influence, making the future of manufacturing brighter than ever.

Advanced Material Innovations

While the epoxy shot molding market has actually long been understood for its resilience and convenience, recent improvements in product advancements are readied to transform its applications. You'll locate that brand-new formulas are enhancing buildings like warm resistance, chemical stability, and impact toughness. These improvements permit the creation of lighter, much more effective parts go to website without sacrificing integrity. Furthermore, bio-based epoxy alternatives are arising, catering to eco conscious manufacturing practices. You can also explore making use of nanomaterials that additionally enhance performance features, enabling you to make items that fulfill stringent market criteria. As these advanced materials become a lot more available, you'll be poised to utilize them, enhancing your item offerings and remaining in advance in a competitive market.

Automation and Performance

With the quick pace of technological improvements, automation is becoming a game-changer in epoxy injection molding. By incorporating automated systems, you can considerably boost manufacturing rate and decrease human mistake. Robotics can take care of repeated jobs, making sure uniformity in quality and precision while freeing your team to concentrate on even more complex issues. Automated surveillance systems likewise supply real-time information, enabling immediate adjustments to maximize the procedure. As you execute these modern technologies, you'll observe better effectiveness, lower production expenses, and quicker time-to-market for your items. Welcoming automation not just simplifies procedures but likewise settings your company to respond swiftly to market needs, keeping you affordable in the ever-evolving manufacturing landscape.

Sustainability in Manufacturing

The integration of automation in epoxy injection molding establishes the phase for a more powerful concentrate on sustainability in production. By utilizing sophisticated innovations, you can minimize waste and power intake in the production process. Automated systems streamline procedures, enabling a lot more exact material use and lowered excess - epoxy injection molding.Additionally, using environmentally friendly epoxy solutions is on the increase, as suppliers seek to develop less harmful products. This shift not just benefits the atmosphere but additionally interest customers who prioritize sustainability.As you embrace these future fads, you'll locate that sustainable methods boost your brand name photo and can cause cost savings over time. Inevitably, focusing on sustainability in epoxy shot molding will certainly place you as a leader in liable production

Frequently Asked Questions

Exactly How Does Epoxy Shot Molding Contrast to Typical Molding Methods?

Epoxy injection molding uses far better accuracy and toughness compared to conventional approaches. You'll find it generates more powerful components with less waste, enabling for intricate layouts that meet requiring specifications without sacrificing top quality or performance.

What Safety Preventative Measures Should Be Taken When Utilizing Epoxy Resins?

Can Epoxy Shot Molding Be Utilized for Custom-made Styles?

Yes, you can certainly make use of epoxy injection molding for custom designs. It enables for intricate shapes and exact describing, making it suitable for producing one-of-a-kind elements tailored to your certain requirements and applications.

For how long Does the Epoxy Curing Process Normally Take?

The epoxy treating procedure normally takes about 24 to 72 hours, depending on the details formulation and ecological problems - epoxy injection molding. You'll desire to guarantee perfect temperature level and humidity for the very best results throughout curing

What Is the Cost-Effectiveness of Epoxy Injection Molding?

Epoxy injection molding's cost-effectiveness originates from its sturdiness and very little waste. You'll find that it decreases manufacturing costs with time, enabling you to develop high-quality products without damaging your budget or sacrificing performance. As the automotive industry continues to develop, epoxy injection molding plays an important function in improving lorry efficiency and longevity. Epoxy injection molding is revolutionizing the aerospace sector by providing lightweight, durable elements that enhance airplane performance. By using epoxy, you're profiting from its superb thermal and chemical resistance, making it ideal for numerous aerospace applications.Imagine the capacity of making use of epoxy in elements like wing frameworks or body components. When you select epoxy shot molding, you're improving your items' resilience and stamina significantly. Improved effect resistance is one of the standout advantages of epoxy injection molding, making Learn More Here your items not just a lot more resilient however also considerably stronger.